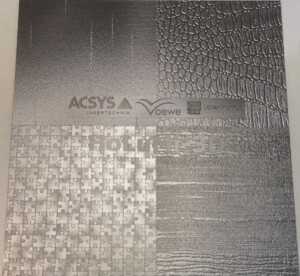

Thanks to a collaboration between MOEWE, the Mittweida-based company ACSYS Lasertechnik GmbH and the Laserinstitut Hochschule Mittweida, a world first has been created as part of the Holumi 3D (GRAVOmer-Verbund) project: the application of fast laser micro-engraving with a polygon scanner in an industrial machine. This will enable greater laser power to be utilised in future and the engraving process to be further accelerated. One field of application for the new technology is, for example, the micro-engraving of printing rollers, as required by the Frankenberg-based company Sächsische Walzengravur GmbH.

Optimum parameters were found in the project, so that a high power of 60 W with a high scanning speed of 40 m/s could be utilised for USP lasers. This scanning speed can only be achieved with a polygon scanner with a short focal length and large aperture. The project collaboration made it possible to solve difficult control and data flow problems and to integrate the scanner into a laser engraving machine for large surfaces so that the high scanning speed could ultimately be precisely applied to the surface. It had to be ensured that the enormous amount of data generated by the high resolution could be processed at the necessary speed. There had to be no transitions at the connection points of the scan fields and no line jumps must be recognisable when the print roller rotates. This was all achieved in an outstanding manner.

MOEWE or ACSYS will be happy to answer any enquiries about the new technology.

You can find more information about the research project here.

Text: R. Ebert

Pictures: ACSYS Lasertechnik GmbH