Options for all polygon scanners

Real-time shifter / motion tracking

Laser processing on moving objects (processing on the fly) is a big challenge for scan systems. The respective velocity vectors for an x-, y-, or z-movement has to be captured promptly and calculated with the laser tracks to be processed. Especially with very fast or strongly variable speeds, a prompt adjustment and correction of the output vectors is hardly possible with a software solution. This results in positional errors of the laser structure or process variations with regard to the expected processing result.

The MOEWE polygon scanners, on the other hand, can optionally record the velocity vectors and make the position corrections in hardware and this with a recording and calculation time of 5 ns each. This enables extremely fast and high-precision tracking of the laser tracks on the moving object, even at highly variable speeds.

The basic requirement is a fast measurement of the positional displacement of the processing objects. Quadrature signals (A, B, I) or pulse/direction signals with high resolution and thus fast sequences (up to max. 100MHz), which can usually be extracted directly from various position or encoder measuring systems, are particularly suitable for this purpose. More complex position protocols with intermediate hardware/software logic do not meet these requirements.

Delivery: Update, real-time shifter logic core for FPGA ; high-speed inputs/outputs

Synchronization of several polygon scanners

The degree of utilization of the laser is limited by the facet length and amounts with a polygon scanner of the PM series max. 60% with full utilization of the scan field. By interconnecting several polygon scanners, however, the laser source used can be used almost completely. The prerequisite is that the laser radiation can be quickly switched between two or more polygon scanners.

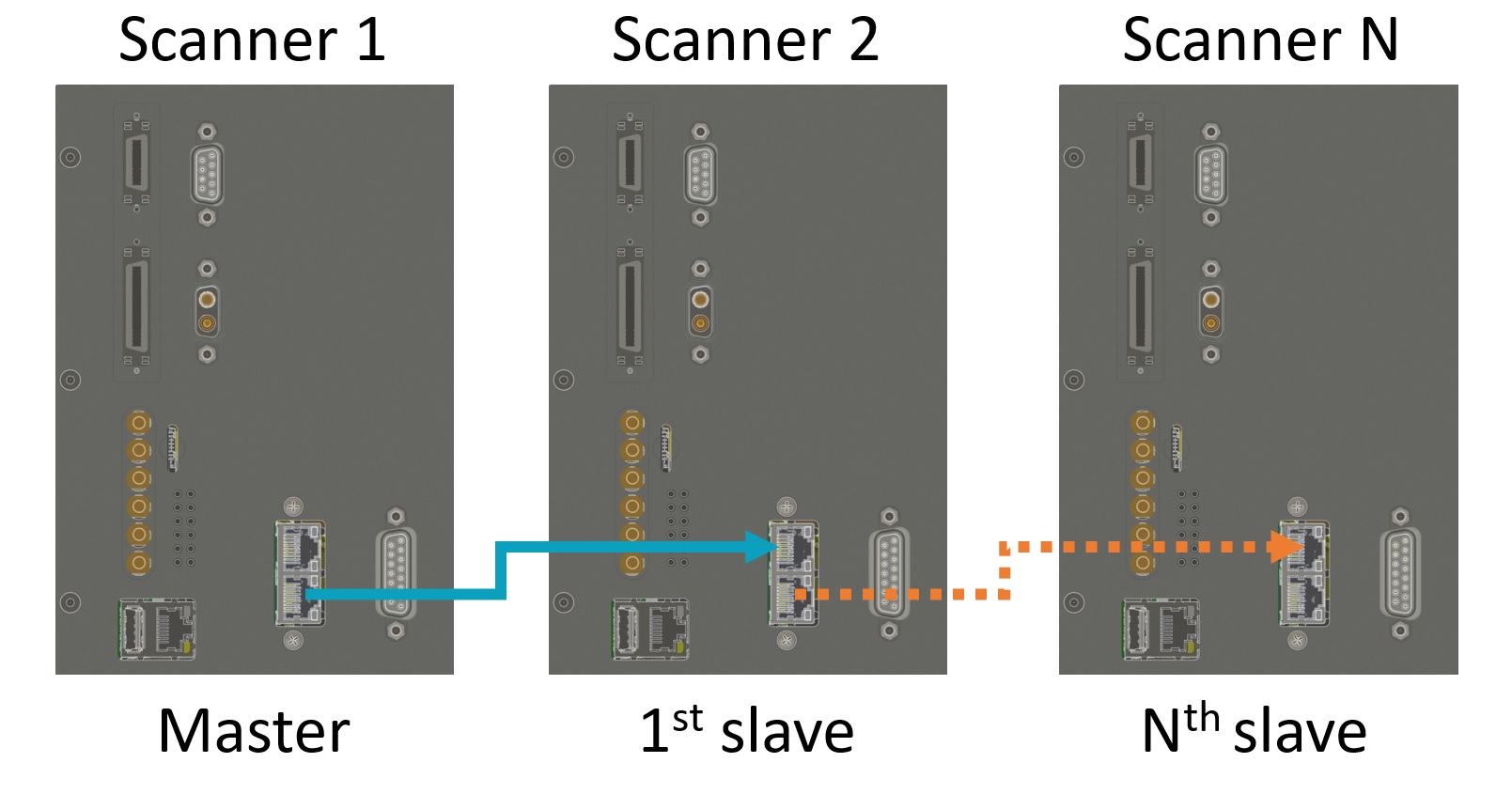

In order to operate a laser source with several polygon scanners, these must be precisely synchronized with regard to rotation frequency and phase position. This is done by linking a master scanner with one or more slave devices. The active link with downstream hardware logic ensures that all downstream scanners run in the correct phase. The desired phase shift between the scanners can be freely selected. With two scanners, a phase or path difference of half a facet length (opening angle) is selected and 50% of the laser radiation is switched back and forth between the scanners. If more than two devices are to be synchronized, the path difference is reduced accordingly.

Delivery: Update, real-time sync logic core for FPGA; high-speed link interfaces with RJ45 sockets, laser signal synchronization (external hardware box)