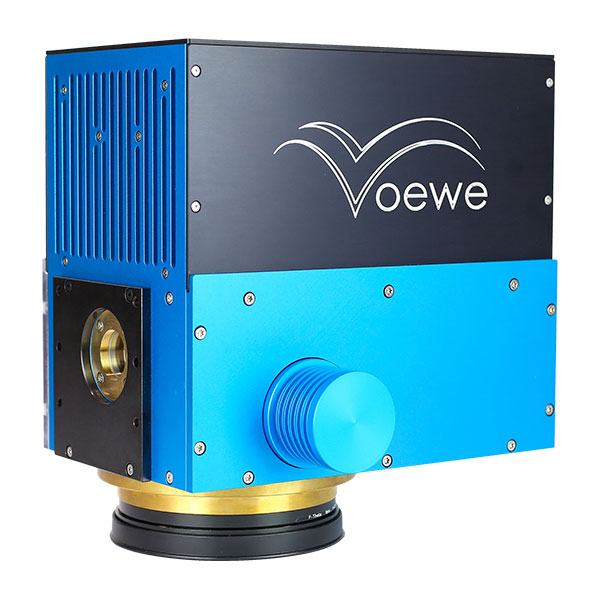

Polygon scanner

Polygon scanners or polygon mirror scanners enable ultra-fast beam deflections.

The laser beam is reflected on a fast-rotating polygon with high reflective surfaces. The mechanical angle of the polygon wheel is transferred into a deflection angle of the beam. Using rotation speeds of some 1,000 or 10,000 rpm, beam deflection speeds in the range of 10,000 – 100,000 °/s are obtained. With suitable objectives (e.g. F-theta-objectives with 420 mm focal length), scan speeds of more than 1,000 m/s can be realized in the working plane.

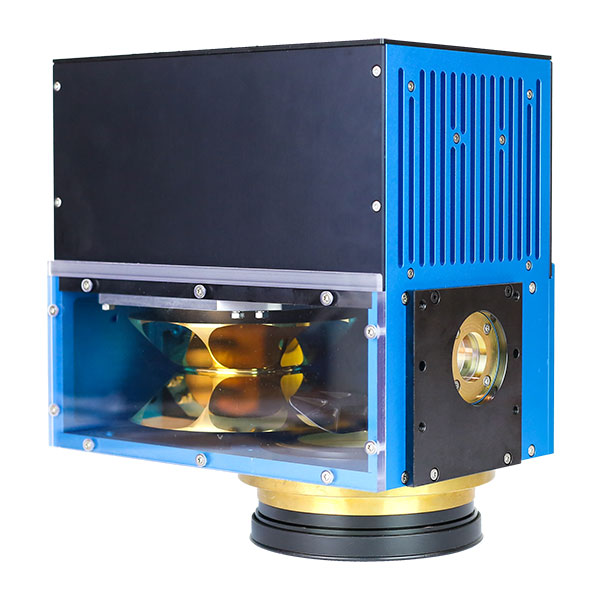

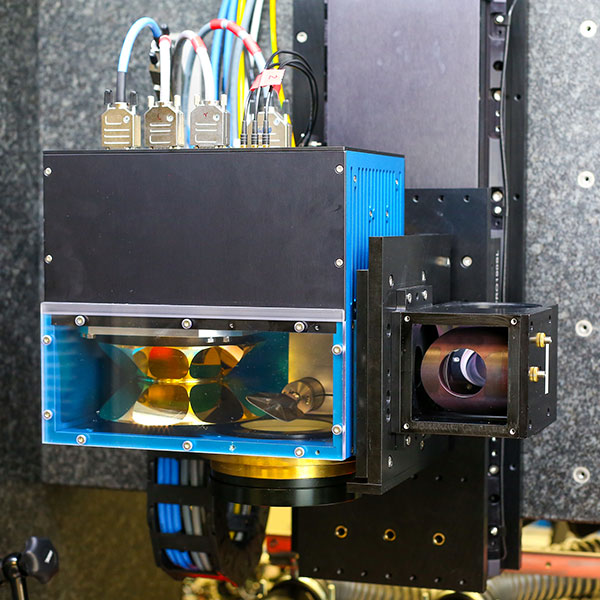

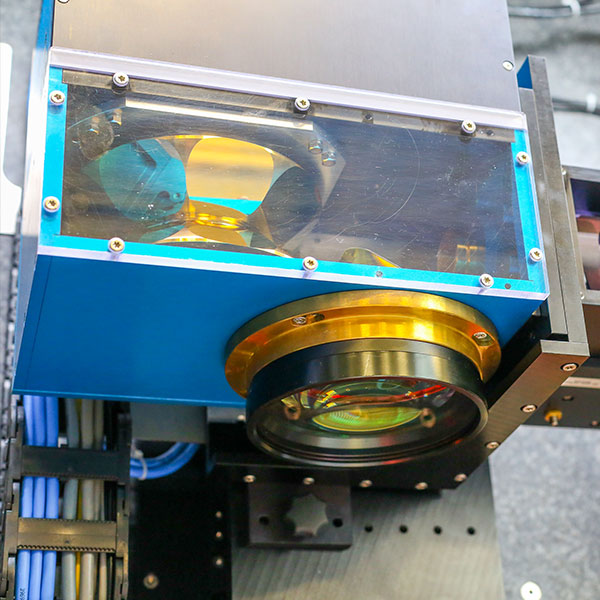

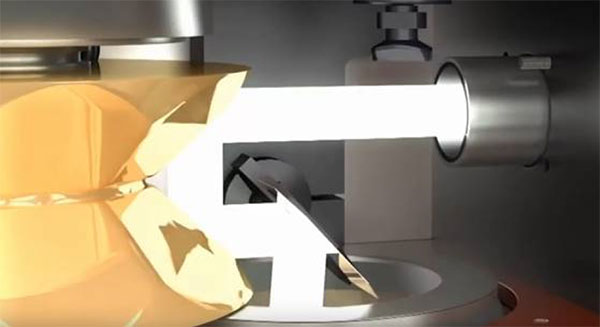

MOEWE’s polygon scanners of the PM series stands out with a special, patented double polygon wheel, where the beam is reflected twice, as shown in Figure 1. Thus, systematic scanning field distortions are avoided. At the same time, further advantages can be achieved such as avoiding back reflection in the direction of the incoming beam and avoiding a movement of the optical pivot points during a facet transition.

Conditioned by the working principle, the polygon mirror scans straight line in the same direction. To achieve a two-dimensional scanning field, MOEWE’s scanners of the PM series are equipped with a digital controllable galvanometer scanner, that varies the position of the lines. Consequently, work pieces can be machined without additional axis systems. Nevertheless, a combination with an axis system or another handling system is possible.

The control of MOEWE’s scanners and the processes to be done with it is realized using an integrated FPGA and two ARM-processors. This controlling concept is also patented. The total digitalization of the scanner allows a real-time compensation of manufacturing deviations and further environmental influences, obtaining highest processing accuracy.

Furthermore, a real-time slicing of 3D solid models is possible.

The PM series is suitable for ultra-fast 2D, 2.5D and 3D processing. The large aperture of 30 mm enables high average laser power of much more than 1000 W and small focal spot sizes in the working plane.

Figure © Hochschule Mittweida: Double polygon wheel with galvanometer scanner and modeled laser beam for two-dimensional beam deflection