Polygon Scanners for High-Speed Laser Processing

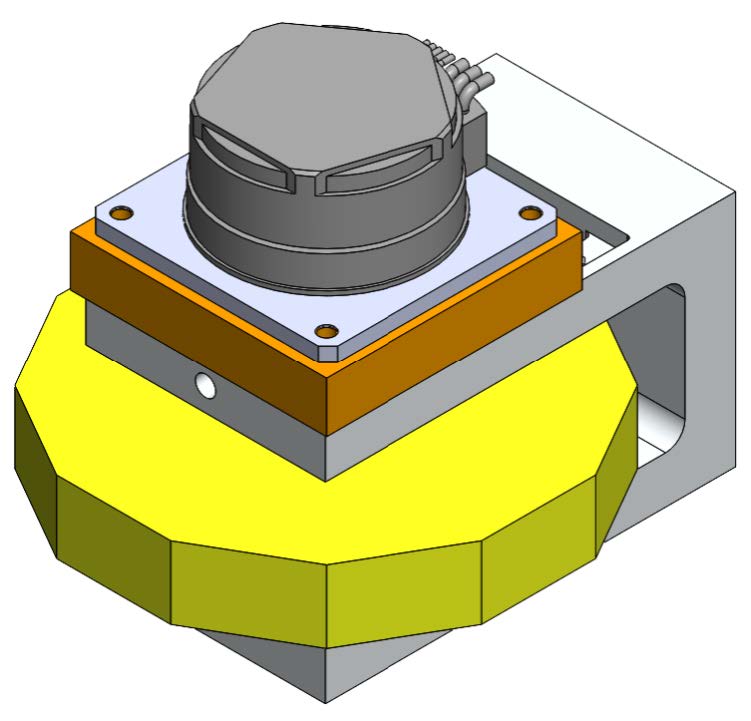

Patented optics & real-time processing

A dual-reflection layout compensates facet transitions optically. An integrated 200 MHz FPGA stamps time marks and corrects tolerances in real time — for precise, reproducible results.

- Patented optical design for minimal distortion

- Real-time data processing via FPGA

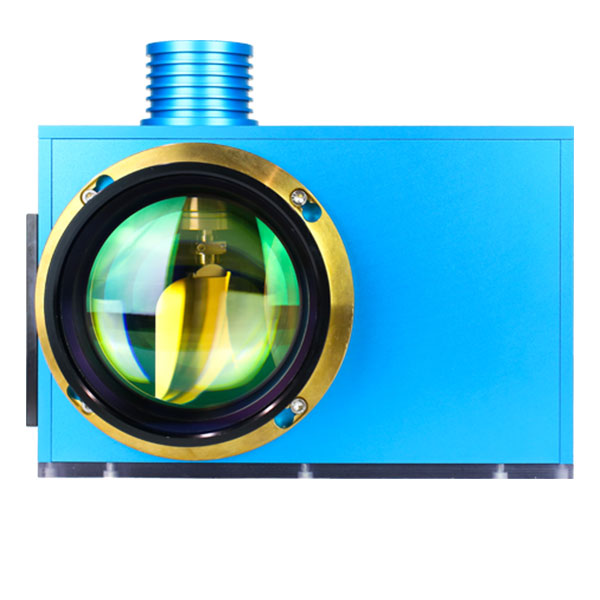

Large clear aperture

A large clear aperture up to 30 mm enables large beam diameters and small spot sizes. All reflective surfaces see only moving beams — allowing efficient deflection of very high laser powers.

- Clear aperture up to 30 mm

- Small spot size (< 10 µm depending on optics/laser)

- Suitable for high-power lasers (> 5 kW)

Speeds > 1,000 m/s

Polygon scanners enable much higher deflection speeds than galvo systems. Even ultrafast lasers with very high repetition rates can be timed precisely — enabling fast, high-resolution processing.

- High productivity in line/area processes

- Efficient use of high laser powers

- Stable path quality at high speeds

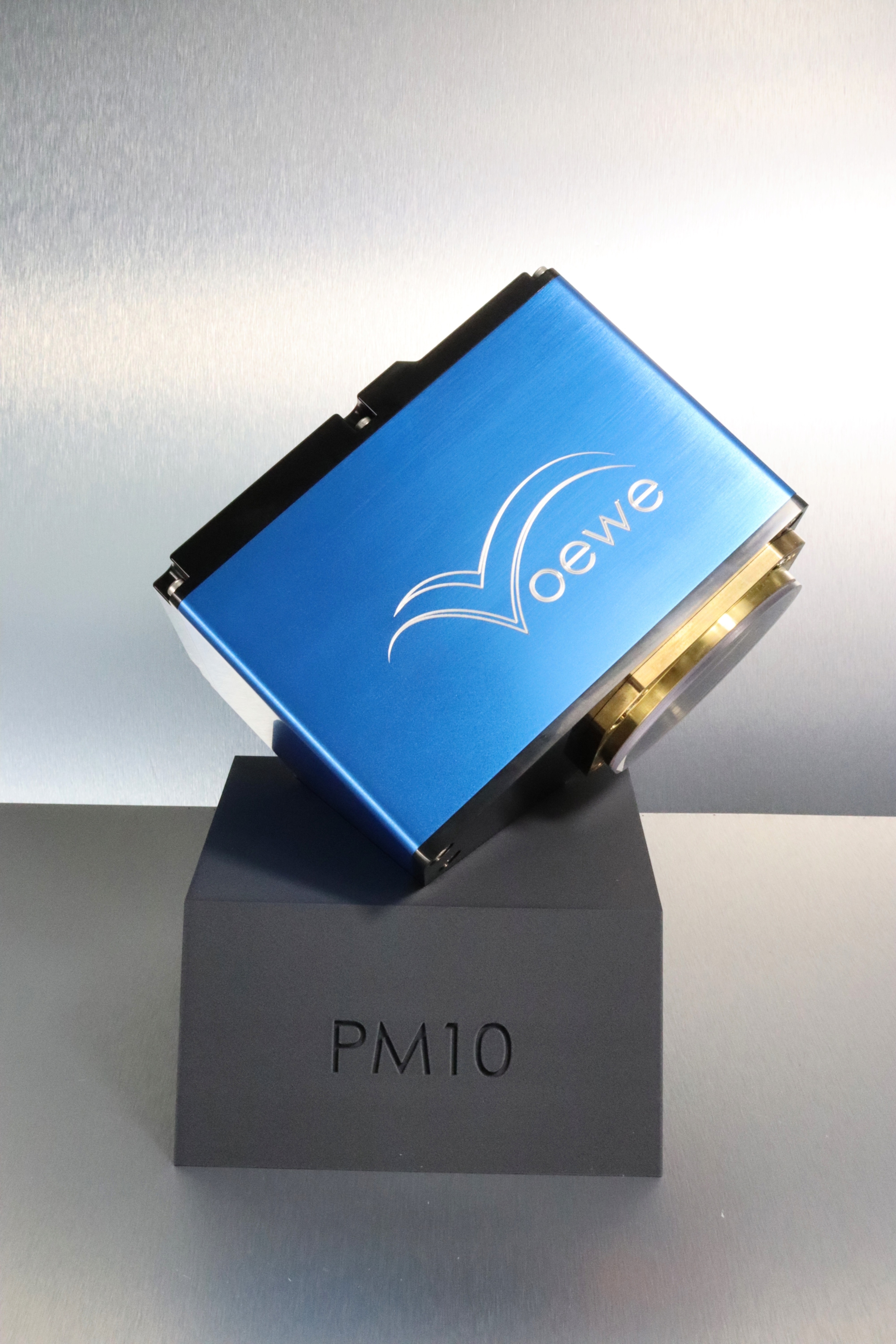

MOEWE Optical Solutions GmbH supplies industrial polygon scanners with large aperture, compact form factor, and high optical robustness. Full digitalization enables high accuracy and real-time integration into external coordinate systems. Tell us about your application — we’ll advise you precisely.

News

Interopto 2025, PACIFICO YOKOHAMA, JAPAN | 11-13 Nov 2025

Our distributor Taihei Boeki Co., Ltd. will be presenting our PM series at Interopto 2025 in Japan. You will find the exhibition stand in Hall C, Stand A-25. More information about the exhibition can be found here.

SPIE. Photonics West, San Francisco, USA | 20–25 Jan 2026

We will once again be exhibiting at the German Pavilion at SPIE. Photonics West in 2026. German Pavillon, booth no. 4205-03.

Sponsor: 14th International Summer School (Fraunhofer IWS & TU Dresden)

We support the Summer School (25–29 Aug 2025) on trends and developments in laser technology. Details here.

Laser World of Photonics | Munich | 24–27 Jun 2025

Meet us in Hall A3, booth 242. More information here.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.