Technology & Functionality of the Polygon Scanner

Technical Fundamentals

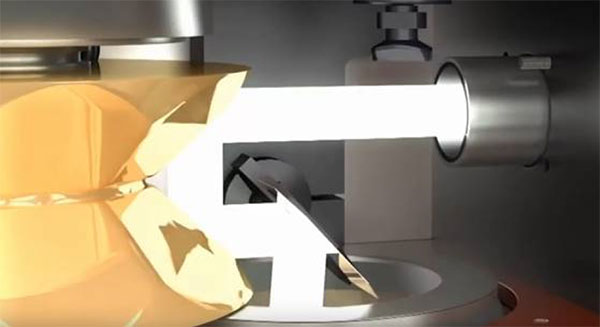

A polygon scanner uses a rapidly rotating polygon mirror, where each facet acts as a small, flat mirror. The rotation continuously deflects the laser beam in one direction — essentially across a line in the processing field. This constant deflection generates highly precise lines at extremely high speeds.

Combination with a Galvo Mirror

For two-dimensional (2D) scanning, a galvo mirror is used. The galvo shifts the line step by step (slow axis), while the polygon drum handles the fast-axis scan.

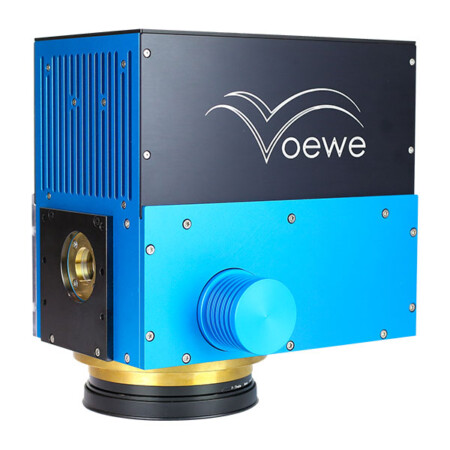

MOEWE-Specific Innovations

Double-Reflection Optics (Patent)

The special feature of the MOEWE PM system is the patented double reflection: The laser beam is reflected twice — compensating facet position errors during rotation, reducing optical distortions, and minimizing back reflections.

Real-Time FPGA Correction

A 200 MHz FPGA monitors and corrects manufacturing, rotational, or positional deviations in real time using time stamps — significantly improving precision and repeatability.

Optical and Mechanical Highlights

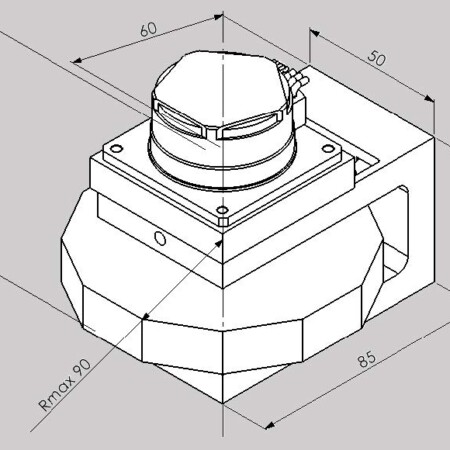

- Large free aperture up to 30 mm enables large beam diameters and fine spot sizes (often < 10 µm depending on optics/laser).

- Very high deflection speed: Polygon scanners achieve much higher speeds than galvos – often > 1,000 m/s. With suitable f-theta lenses (e.g. f = 420 mm), deflection rates of 1,300 m/s are possible.

- High laser power: The systems support laser powers > 5 kW.

- Extremely high repeatability at high speed, ideal especially for raster and area processes such as microstructuring or cleaning.

Applications & Advantages at a Glance

| Advantage | Description |

|---|---|

| Extremely high processing speed | Ideal for large-area processing, raster scanning, and fast microstructuring. |

| High precision | Double reflection + FPGA correction ensure accurate and repeatable results. |

| High performance capability | Supports high laser powers (> 5 kW), large beam diameters, small spot sizes. |

| Robust & process-stable | Mechanically solid, low wear, optimized for continuous industrial operation. |

Conclusion

The MOEWE polygon scanner combines maximum processing speed with precision and robustness. The patented double reflection, real-time FPGA correction, and large aperture enable machining at the highest power and accuracy. Perfect for industrial applications with very high demands in productivity and quality.