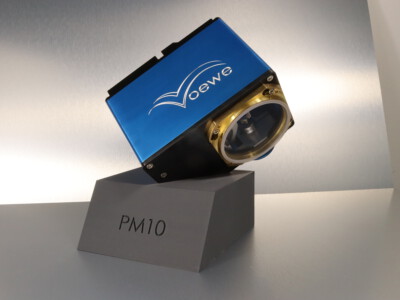

PM 10 – Maximum Precision in Minimal Space

An affordable entry-level model for small and medium laser power

Surface Treatment

Modification

Cleaning

Cutting

Marking

Microstructuring

Drilling

Perforation

2.5D Engraving

LIFT

PM 10 – Base & Options Comparison

| Feature | PM 10 Base | PM 10 with Options |

|---|---|---|

| Clear Aperture | 10 mm | 10 mm (Coatings on request) |

| Laser Utilization (Duty Cycle) | 50 – 70 % | 50 – 70 % (Optimizations depending on optics) |

| Scan Facets / Angles | 8 or 12 facets (±30° / ±15°) | 8 / 12 + custom configurations |

| Max Lines / s | 666 Hz @ 5,000 rpm (8F) / 1,000 Hz @ 5,000 rpm (12F) | Up to 1,000 Hz (configuration dependent) |

| Dimensions (L×W×H) | 170 × 140 × 135 mm | Same, optional mounting accessories |

| Weight | < 10 kg | < 10 kg |

| Power Supply | 24–48 V DC, max. 150 W | Same + special configurations |

| Interfaces | 1× Gbit Ethernet, Laser I/O (SMB), GPIO / Axis I/O | + extended I/O, custom interfaces |

Your Advantages

- Two-dimensional beam deflection allows standalone operation or integration into production lines (axis, roll-to-roll)

- Synchronization of two scanners on one laser source (optional)

- Wide range of applications: laser marking, microstructuring, surface cleaning, drilling, cutting, spot welding, engraving (2.5D), and more

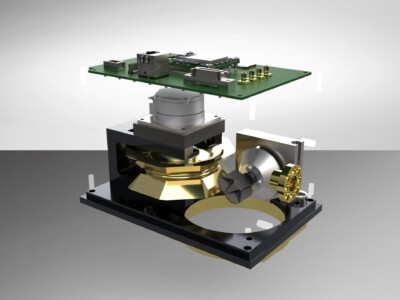

Technical Details

- Dimensions: 170 × 140 × 135 mm

- Weight: < 10 kg

- Clear Aperture: 10 mm

- Max Lines/s: 666 Hz @ 5,000 rpm (8F) / 1,000 Hz @ 5,000 rpm (12F)

- Power Supply: 24–48 V DC, max. 150 W

- Interfaces: 1× Gbit Ethernet, digital Laser I/O, analog I/O, GPIO / Axis I/O

- FPGA On-board Processing, On-board Memory 1–2 GByte

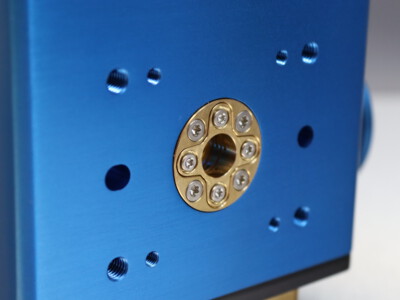

Optics & Mounting

Mechanical Mounting: Adapter and mounting instructions according to drawing. M4 for lens adapter ring (max. screw depth 10 mm), M6 for scanner mounting (max. screw depth 10 mm), keyway hole Ø6 H7 × 20. Extensive support for custom mounting adapters on request.

PM 10 Mini Datasheet